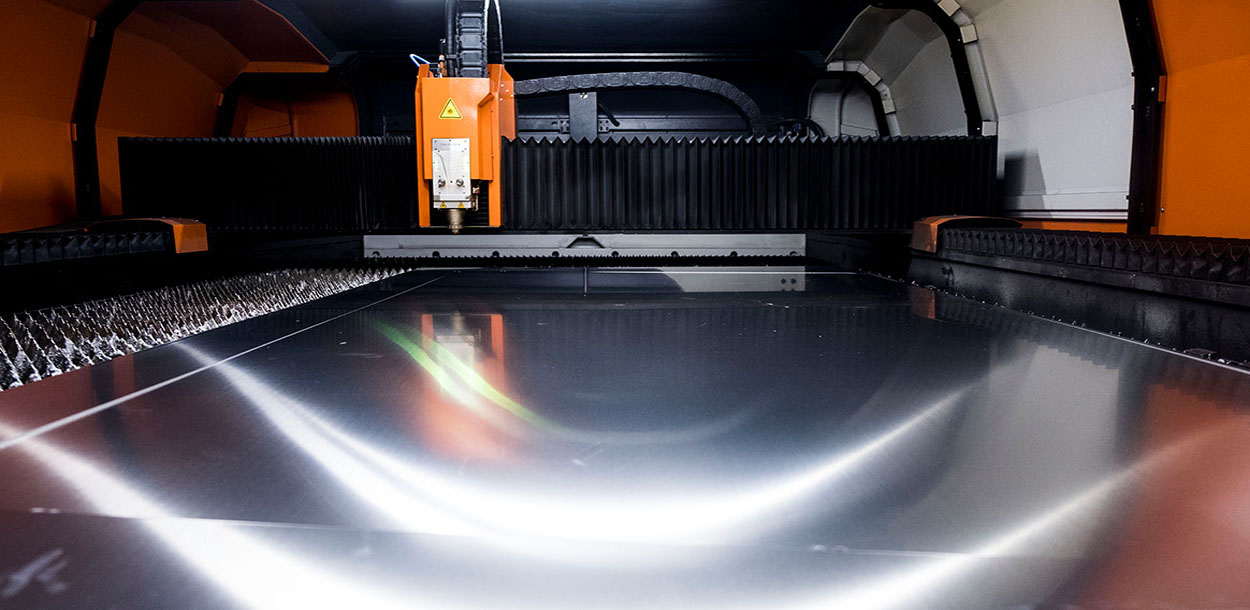

CNC Laser Cutting

Our laser cutting machine, which has been established for high precision and fast cutting processes, is available with a cutting area of 2000mm * 4000mm. When it focus to best, efficiency is highest.

Saving on apparatus and mold from laser cutting operations. Since the workload rests on the machines, errors caused by the human factor are indirectly reduced.

Saving on apparatus and mold from laser cutting operations. Since the workload rests on the machines, errors caused by the human factor are indirectly reduced.

What are the Advantages of Laser Cutting?

• More economical than machining,

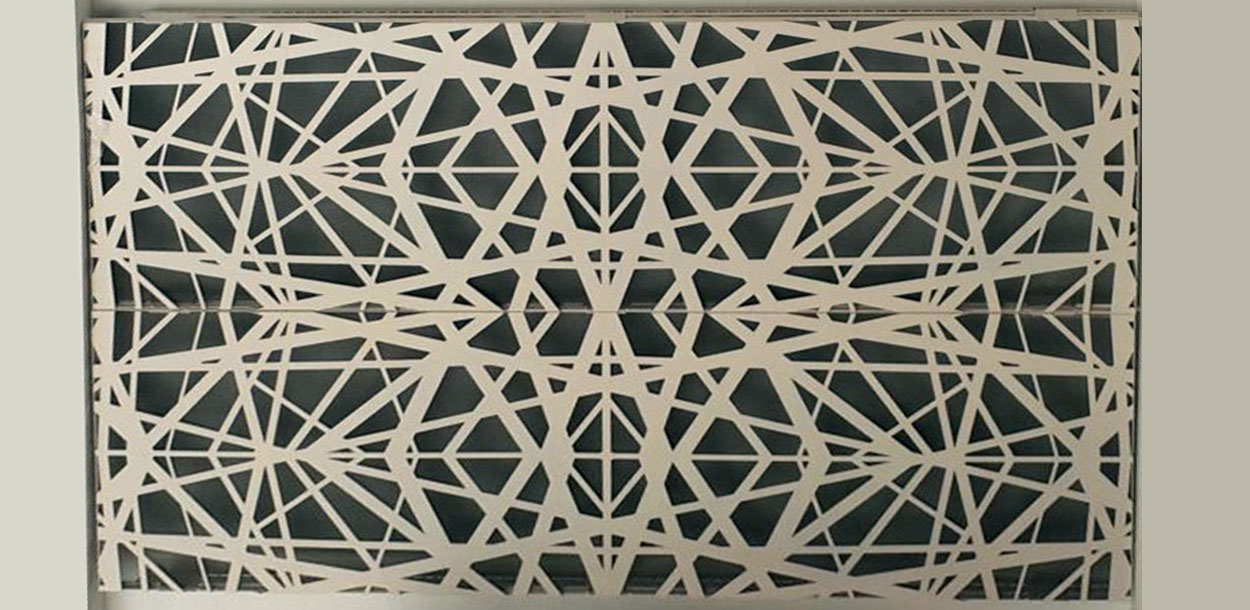

• More flexible working opportunity in design,

• Cutting without burr and with minimum roughness,

• The most efficient use of the material and minimum waste,

• High efficiency and low cost in prototype works in a short time,

• No deformation in the material as there is no contact with the material during cutting,

• Low cost production in a short time without the need for molds in small number of productions.

• More flexible working opportunity in design,

• Cutting without burr and with minimum roughness,

• The most efficient use of the material and minimum waste,

• High efficiency and low cost in prototype works in a short time,

• No deformation in the material as there is no contact with the material during cutting,

• Low cost production in a short time without the need for molds in small number of productions.